Barnes Oil Pump Pressure Adjustment

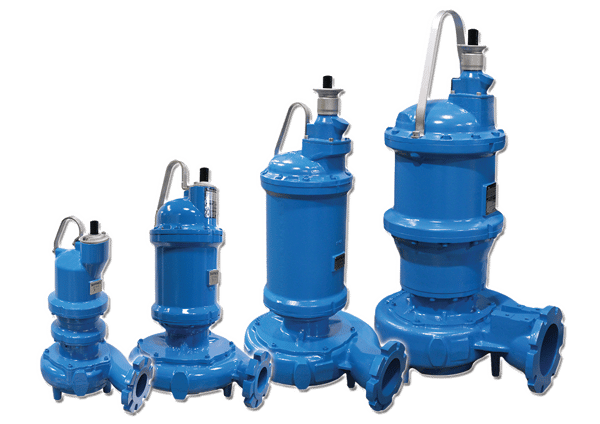

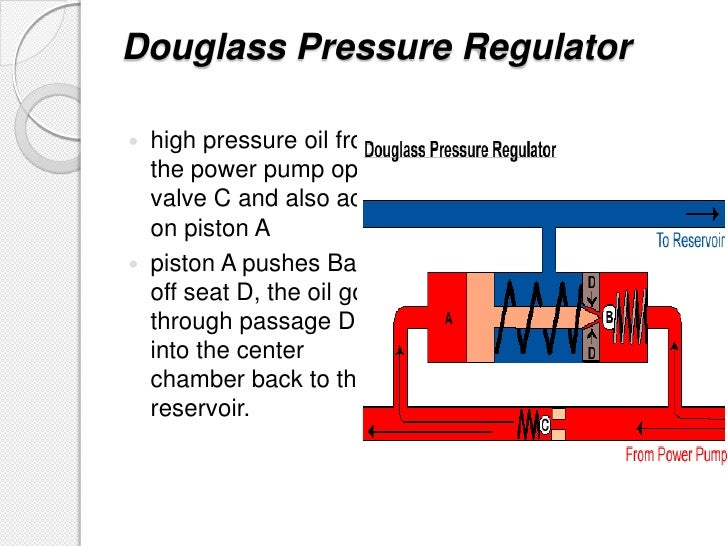

Increasing the unloading valve pressure will require increas ing the pump drive horsepower.

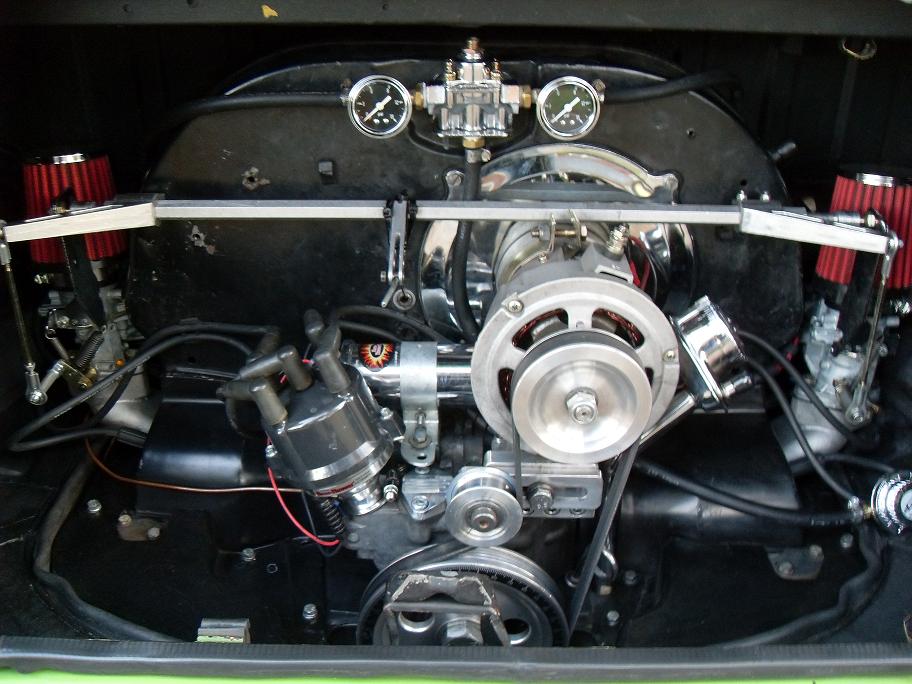

Barnes oil pump pressure adjustment. For quality oil pumps accessories oil system service and repair barnes system inc is here for you. A at the rear of the pressure stage on bottom is a set screw and jam nut. Loosen the jam nut and turn the allen screw in clockwise to increase pressure and counter clockwise to reduce pressure. I have a 410 small block w barnes 4 stage dry sump pump.

Torrance ca 90505 310 534 3844 phone 310. Spool to direct control oil into the servo piston and destroke the pump. Alky express live s again just started the motor yesterday i went to a dry sump system barnes pump the pump has a adjustment for pressure. Have a 360 sprintcar barnes 4 stage wix filter synth oil start engine and have 80 lbs oil take car to track in racing condition oil pressur droped to 50 lbs oil pressure screw turned in tight put a fram filter on and pressure went to 75 lbs on track with wix filter oil pressure dropped when warm to 50 lbs every time when warmed up.

If the engine pressure pump has more capacity than that required to maintain suitable oil pressure at idle when the engine and the oil are both hot it will waste power at any speed above idle. On our 3 4 stage and up drysump pumps with a pressure stage not scavenge only pressure can be adjusted. I just need to adjust oil pressure via oil pump but how. According minister power optimal engine working parameter it should be at least 20psi at idle and 70psi at 5000rpm falling to 60psi at 8000rpm engine just have been rebuilt and do not have any problem.

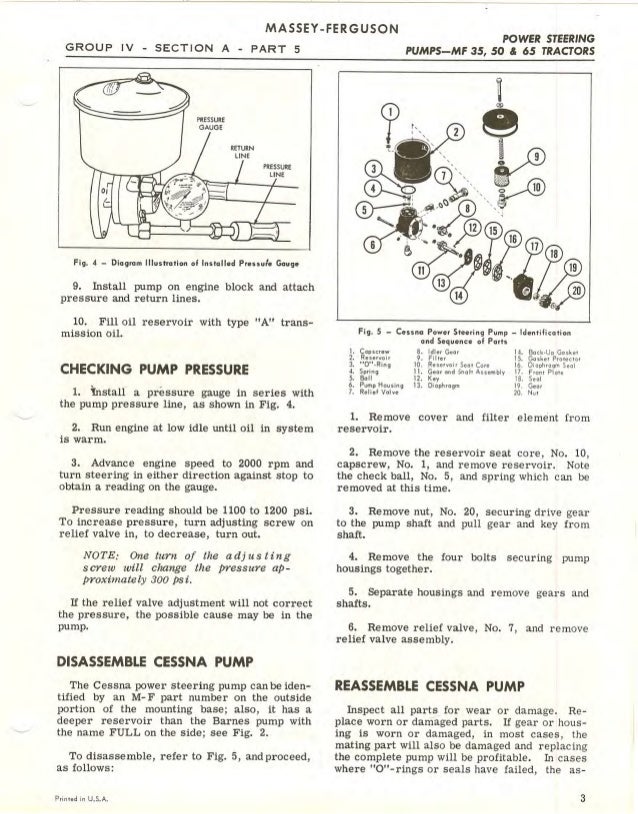

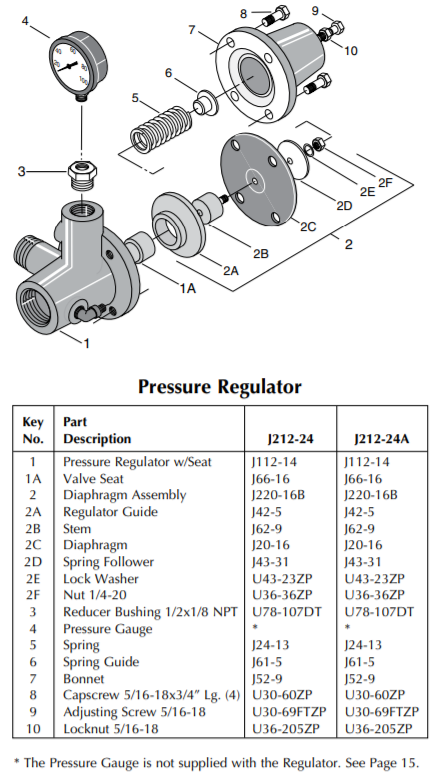

Idle cold it has 80 psi oil pressure w 20 50 oil. Factory preset with a 400 900 psi adjustment range. Q how do i adjust the oil pressure on the dry sump pump. The pump will maintain a flow level that keeps the pressure drop across the.

Linbob on june 15 2011 at 02 01 15 pm. Or are ther different springs as well. To relieve pressure is it simply a matter of adjusting the screw on the end of the pressure stage. These facts about oil pump operation and flow requirements generally cause the capacity of an engine pressure pump to be defined by the oil pressure requirements of the hot engine at idle.

On the rear bottom inlet side of the pump there is a hex nut and threaded adjusting screw pointing up vertically loosen the hex nut and with an allen wrench screw the adjuster in clockwise to increase pressure and counter clockwise to back it off reduce pressure. On a pace dry sump duratec engine on a track day when oil is hot oil pressure could be as low as 10psi at idle and 50psi at 5000rpm. Barnes systems inc 3162 kashiwa st. It idle at 80 psi blip the throttle it goes to 97 psi this is after the oil is at 160 temp i run 8100 rpm the rule of thumb i normally go by is 10 psi for every 1000 rpm.

Pressure gauge required when adjusting unload valve. Maximum recommended loading for 3 hp electric motors and 5 hp engines is 550 psi. It is a 9017 pump driven directly off the cam. Hydraulic pump motor division piston pump controls problem.

Do this when the engine has been run and oil is warm.