Barnes Oil Pump Disassembly

As a result of crane pumps systems inc constant product improvement program product changes may occur.

Barnes oil pump disassembly. As a result of crane pumps systems inc constant product improvement program product changes may occur. With over 20 years of experience in the industry. Refer to disassembly and assembly engine oil pump remove. Read all instructions in this manual before operating pump.

Remove the oil pump. Read all instructions in this manual before operating pump. Oil filter block off plate by barnes. Barnes installation and operation manual submersible fountain pump.

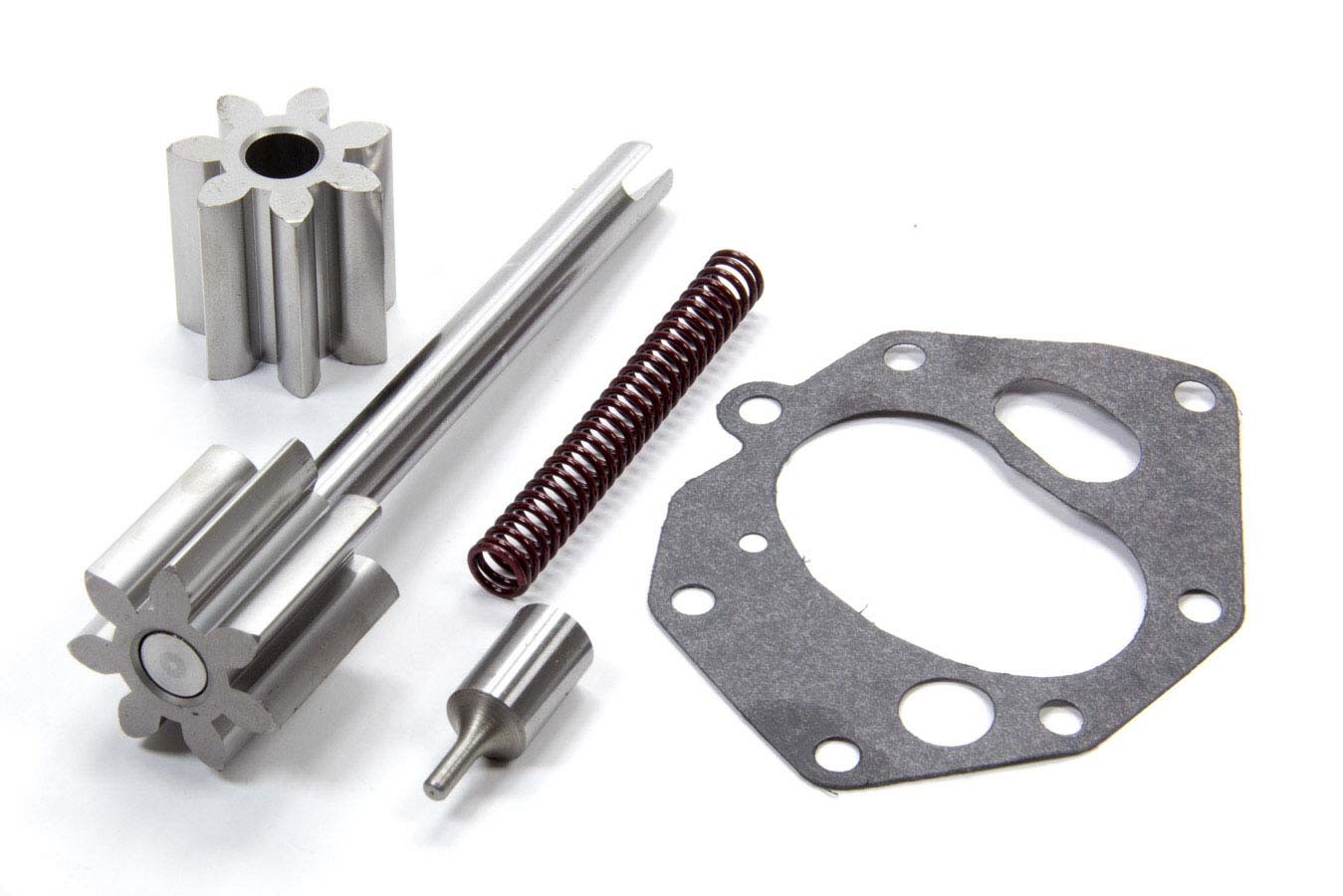

Barnes installation and operation manual submersible non clog pump important. Use tooling a to remove the shaft. Remove retainer 3 from the bypass valve. Remove the bolt that holds drive gear 1 on the shaft.

This product is a must have for those who want to improve overall pump performance. As such crane pumps systems reserves the right to change product without prior written notifi cation. Upon receiving the pump it should be inspected for damage or shortages. As such crane pumps systems reserves the right to change product without prior written notifi.

Barnes 2sev2042l part 104192 2hp 460v manual single seal sewage pump with 2 discharge and vortex impeller 1 093 04 barnes part 104894 0 5hp 200 230v 3 phase 1750rpm 3se594l model sewage pump. Barnes oil tank services ltd is one of the leading specialists in oil tank installation repair and removal of oil tanks for home agricultural factory or construction sites in the south east. For quality oil pumps accessories oil system service and repair barnes system inc is here for you. Read all instructions in this manual before operating pump.

All surfaces should then be sprayed with a rust inhibiting oil. Barnes installation manual submersible grinder pump important. It provides exceptional functionality and durability resulting in years of hassle free operation. Page 1 barnes barnes service manual ogp 2 hp pump important.

Pump should be stored in its original shipping container and on initial start up rotate impeller by hand to assure seal and impeller rotate freely. As such crane pumps systems reserves the right to change product without prior written notifi. If damage has occurred fi le a claim immediately with the company that delivered the pump. Remove the key from the shaft.