Automotive Water Pump Impeller Design

I am just going to show the basic design of it latter i will upload a complete video of it wi.

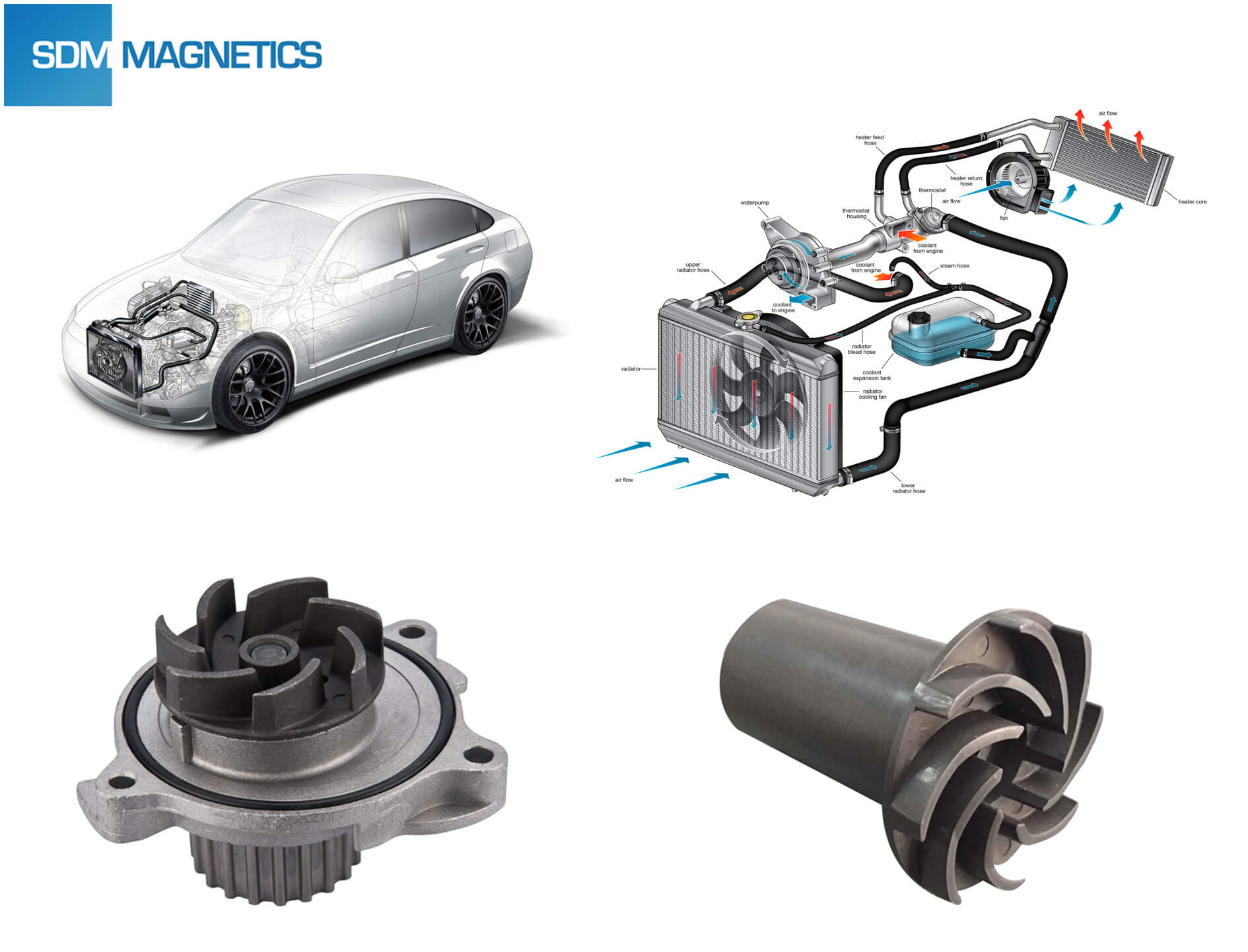

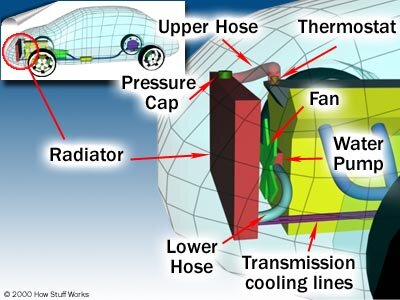

Automotive water pump impeller design. Impeller geometries that enhance efficiency and provided the needed mechanical integrity and dimensional stability in the face of continual immersion in aggressive coolant solutions at temperatures to 130 c. Flowkooler pumps are designed to move water more efficiently from the radiator to the block to keep you cool. In order to investigate the water pump characteristic a dedicated automotive cooling simulator test rig was designed and. With the metal impeller design you do run a slight risk of possibly gouging the case however there are auditory warnings from the bearing in most cases well before enough wobble causes damage.

It is amazing the amount of engineering that went through on this. Centrifugal pump design and manufacturing has been around for over 200 years. If there were an ideal impeller vane number it seems likely someone would have discovered it by now. Water pump design and operation the water pumps which are 4 to 15 inches in diameter 10 to 38 cm and 3 5 to 8 inches.

However just because an ideal vane number has not yet been established is not sufficient reason to consider it doesn t exist. I am told it is a higher capacity than the auto pump. Regardless of the material used for the impeller it should be replaced at 30 50k intervals depending on usage and risk avoidance preferences. This is the new marine water pump.

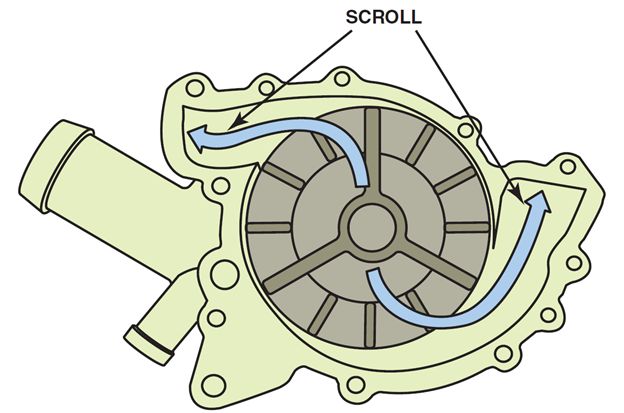

Occasionally diverters are necessary in the water pump scroll to equalize coolant flow between the cylinder banks of a v type engine in order to equalize the cooling. December 12th 2015 part5 bearing step. This is very cheap and reliable home made water pump impeller. July 2018 at 20 48.

This was a good read that was informative and easy to understand. Geometry for a shrouded impeller andy lee 12. The design does not exactly resemble the pump used in automobiles these days. If the seal of the water pump fails coolant will leak out of the.

Automotive water pump automotive water pump loading. The crucial water pump parameters are the head power and its efficiency. Some refer to the improvement in flow efficiency as a gain in horsepower other call it a conservation of horsepower. A poorly designed water pump casting and impeller can result in wasted horsepower.

However i have discovered that some components on the engine are the same as the auto components.